Nov 11, 2024

Rob Hussey

What is Smart PPE?

Smart Personal Protective Equipment (PPE)

For decades, PPE has served as a critical protective measure, but it has remained largely unchanged. Today, advancements in wearable technology are reshaping how safety gear functions, turning traditional PPE into a connected system that enhances worker protection and operational efficiency.

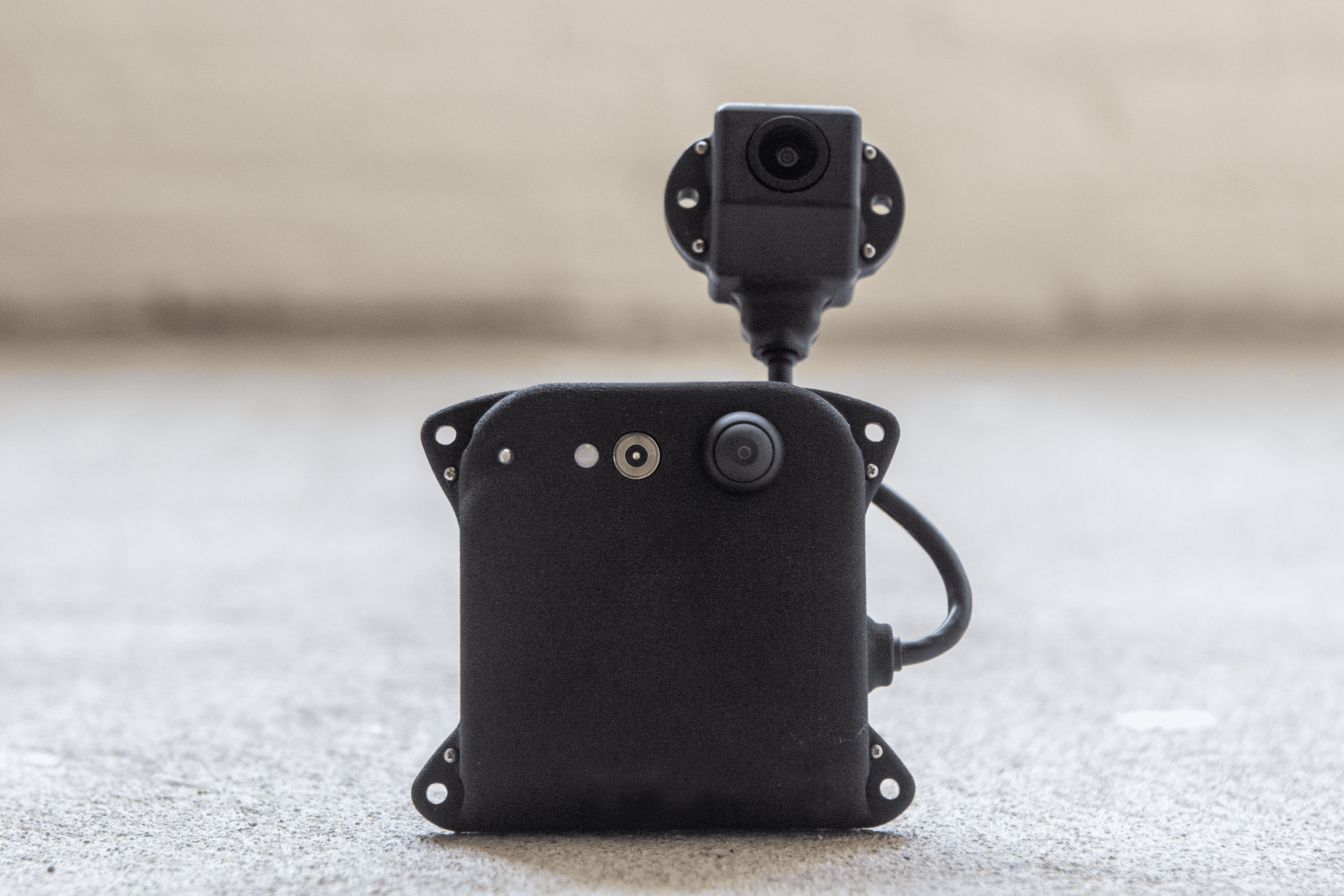

Smart PPE integrates sensors, live-streaming cameras, and networked intelligence into helmets, hard hats, respirators and other equipment. These enhancements provide real-time data on worker safety, site conditions, and operational risks, allowing organizations to take proactive measures instead of reacting to incidents after they occur.

For OEMs, integrating Smart PPE supports real-time monitoring, remote oversight, and automated safety processes. By incorporating Smart PPE, manufacturers position themselves at the forefront of workplace safety innovation.

Enhancing Workplace Safety

Traditional safety programs rely on periodic inspections and manual reporting, which can lead to delays in hazard detection and response. Smart PPE changes this dynamic by providing continuous monitoring, instant communication, and automated safety alerts, ensuring that potential risks are addressed in real time.

Key components of Smart PPE include:

Wearable sensors: Track environmental hazards, worker biometrics, and location in real time.

Live video streaming: Provides supervisors and remote teams with a direct view of field conditions.

Integrated connectivity: Uses 5G, industrial Wi-Fi, and cloud-based platforms to centralize safety data.

These features help organizations streamline safety processes, improve situational awareness, and mitigate risks before they escalate.

Wearable Sensors

Smart PPE uses embedded sensors to monitor various safety parameters, providing real-time insights into workplace conditions:

Biometric monitoring: Tracks heart rate, fatigue, and exertion levels, helping prevent overexertion-related incidents.

Gas detection and air quality sensors: Identify toxic gases and other environmental hazards before they reach dangerous levels.

Live location tracking: Ensures visibility in confined spaces and hazardous areas, improving response times in case of emergencies.

By leveraging this data, organizations can shift from reactive to proactive safety management.

Wearable Live-Streaming Technology

Smart PPE integrates live video streaming to provide real-time visibility into field operations. This capability benefits organizations by:

Facilitating remote diagnostics: Experts can assess issues without traveling to the site, reducing downtime.

Improving communication: Workers receive real-time guidance from supervisors, enhancing efficiency and accuracy.

Supporting documentation and training: Live footage can be recorded for compliance reviews, training, and incident analysis.

With this level of connectivity, teams can collaborate more effectively, reducing the need for in-person supervision while maintaining operational control.

Industry Applications of Smart PPE

Fire & Emergency Services

Smart PPE enhances situational awareness for firefighters and emergency responders by:

Providing real-time video feeds to command centers for informed decision-making.

Monitoring biometric data to prevent overexertion.

Detecting hazardous air conditions through connected respirators.

Utilities & Field Services

Utility workers benefit from Smart PPE in remote and high-risk environments by:

Using live-streaming for remote troubleshooting to reduce unnecessary site visits.

Alerting workers to environmental risks such as electrical hazards.

Providing GPS tracking to ensure team coordination and safety.

Oil, Gas & Mining

In energy and mining operations, Smart PPE helps prevent exposure to hazardous conditions by:

Detecting toxic gases before they pose a threat.

Streaming real-time video from confined spaces for remote monitoring.

Analyzing past safety incidents to improve future risk management.

The Evolution of Smart PPE

As Smart PPE technology continues to advance, new capabilities will further enhance workplace safety and efficiency:

Augmented Reality (AR) interfaces: Display critical safety information directly in a worker’s field of view.

AI-driven risk detection: Analyze real-time data to identify early warning signs and predict hazards.

Automated compliance tracking: Reduce administrative burdens by automatically documenting safety protocols.

OEMs that embrace these innovations will lead the next wave of workplace safety advancements, ensuring their products meet the evolving demands of connected safety solutions.

As industries move toward data-driven safety models, Smart PPE is becoming an essential part of modern workplaces. By leveraging real-time monitoring, AI-driven insights, and seamless connectivity, organizations can build a safer, smarter, and more responsive safety infrastructure.

Rob Hussey

Head of Growth

[ Blog ]