Nov 19, 2024

Ryan Finkelstein

“Intrinsically Safe": What It Means and Why It Matters

Understanding What's Meant by "Intrinsically Safe"

In industries like oil and gas, mining, manufacturing, and firefighting, working in hazardous environments is often unavoidable. These settings are filled with potential risks such as flammable gases, vapors, or combustible dust. In such environments, safety is paramount, and one crucial concept that frequently comes up is "intrinsically safe."

But what exactly does "intrinsically safe" mean? Let’s break it down.

What is Intrinsic Safety?

"Intrinsically safe" refers to a design philosophy and standard for electrical equipment and devices used in hazardous areas. The goal of intrinsic safety is to prevent sparks or excessive heat that could ignite a flammable atmosphere. This is achieved by limiting the electrical energy available in the device—ensuring that even in the event of a fault, the equipment cannot release enough energy to ignite a potentially explosive atmosphere.

This concept is critical in environments classified as hazardous, where a mix of flammable substances and oxygen could create an explosive atmosphere. Examples include oil rigs, grain silos, chemical plants, and underground mines.

How Intrinsically Safe Devices Work

Intrinsically safe devices are engineered with special precautions to reduce energy levels in their electrical circuits. These precautions include:

Energy Limitation:

Components are designed to limit the amount of electrical current and voltage.

Circuit Protection:

Devices use barriers, such as resistors and fuses, to restrict current and prevent overheating.

Material Choices:

Materials used in construction are non-sparking and heat-resistant.

By adhering to strict design standards, these devices minimize the risk of igniting hazardous environments, even during a malfunction.

You can find more information on Intrinsically Safe equipment on the Intrinsically Safe Store website.

Certifications and Standards

For a device to be considered intrinsically safe, it must meet specific international standards. Some of the most widely recognized certifications include:

ATEX (Atmosphères Explosibles): Common in Europe.

IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres): A global standard.

UL (Underwriters Laboratories) and FM (Factory Mutual): Often used in the United States.

These certifications ensure that a device has been rigorously tested and meets the safety requirements for hazardous areas.

Why Intrinsically Safe Matters

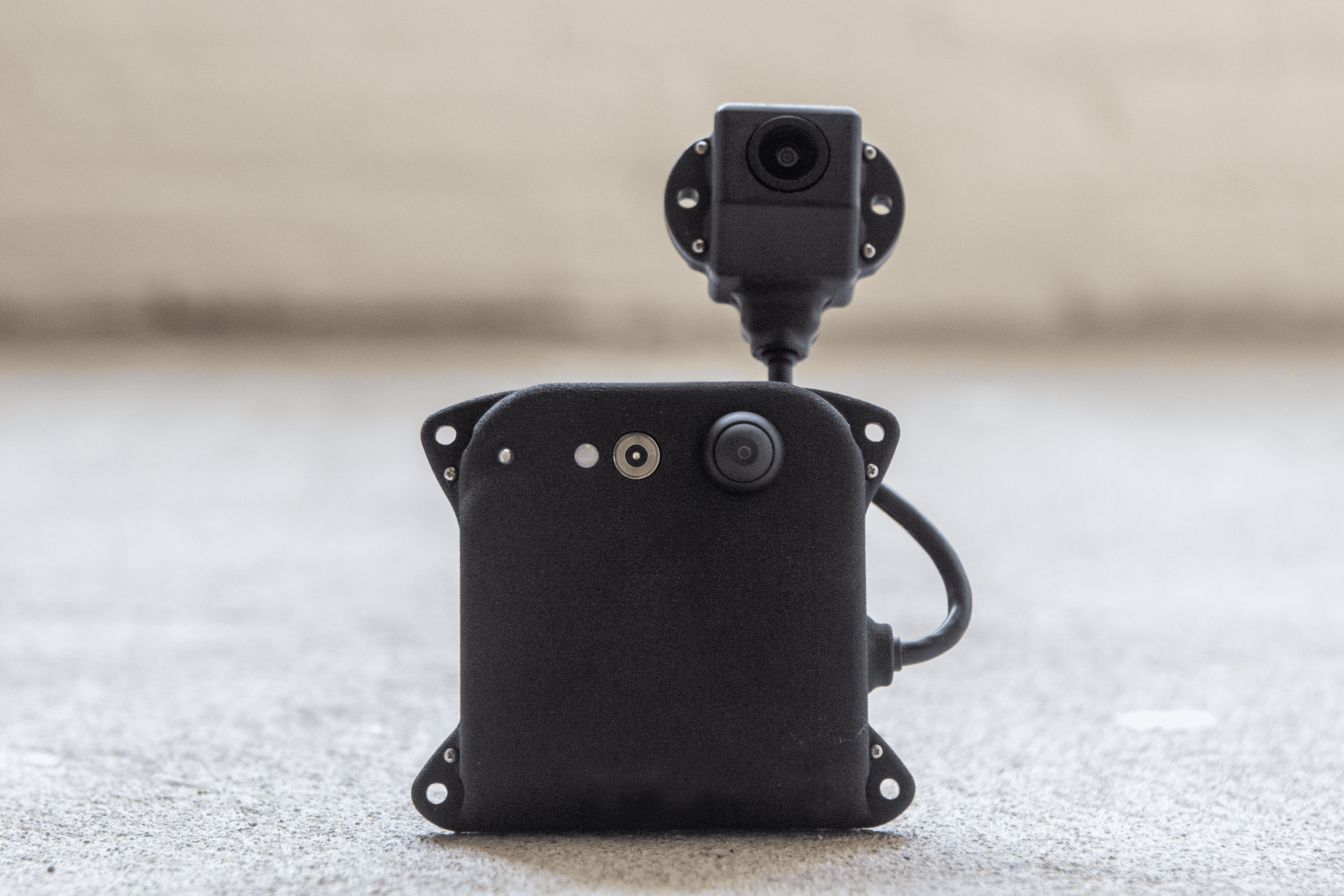

Using intrinsically safe equipment is not just about compliance; it’s about ensuring the safety of workers and protecting critical infrastructure. For example, wearable devices like cameras, communication tools, or sensors used in confined spaces or hazardous zones often need to be intrinsically safe to operate without posing additional risks.

Intrinsic Safety in Modern Technology

Today, intrinsic safety is becoming increasingly important as more industries adopt wearable technology, IoT devices, and advanced electronics. ActionStreamer, for instance, offers wearable video streaming solutions that can be integrated into personal protective equipment (PPE), ensuring compliance with intrinsic safety standards while providing real-time video and data capabilities in hazardous environments.

Conclusion

Intrinsic safety is more than a technical standard; it’s a safeguard for lives and assets. By ensuring that devices used in hazardous areas are incapable of igniting explosive atmospheres, industries can operate with greater confidence and security. When selecting tools or equipment for hazardous environments, always look for the appropriate certifications to ensure they meet the required safety standards.

Ryan Finkelstein

Head of Media and Production

[ Blog ]